What is Oxidized Bitumen?

Oxidized bitumen, also known as blown bitumen, is produced by passing air through penetration grades, giving it more rubbery properties than its original formula. This hard bitumen is widely used in various industries, including the piling industry, roofing felts, waterproofing, sound dampening felts, and under carriage sealant in the automotive industry. It is produced through continuous or staggered blowing processes, with the most popular grades being 95/25, 85/25, 90/40, and 115/15. Other grades can be produced upon customer request.

Oxidized bitumen is an excellent sealant for high-temperature applications due to its high softening temperatures. Blown bitumen should be broken into small pieces and heated slowly to 220ºC to 230ºC. It is water-resistant, highly flexible, and durable, with chemical stability. It is also chemically stable and highly flexible, making it a highly sought-after compound in various applications.

Grade of Oxidized Bitumen

This kind of bitumen comes in multiple types. Low oxidized bitumen options include 75/25, 75/30, 85/25, 85/40, 95/25, and 90/40. Medium ones consist of 90/10 and 90/15, while the hardest oxidized bitumen includes 115/15, 110/15, 105/5, 105/15, 105/35, and 150/5.

If you are interested in seeing the complete process of producing bitumen and getting to know its steps, please click on the link below. This link will lead you to a comprehensive and detailed experience that presents all its details and steps clearly and clearly.

Oxidized Bitumen Production: Methods & Process

Oxidized bitumen manufacturing involves heating and transferring bitumen from a furnace to an oxidation unit, with air blowing increasing the bitumen volume up to 70%. The process stiffens the bitumen, causing changes in its softening point, penetration value, and viscosity. To control the temperature, a water jacket or water spray facility can be placed on the reactor head, reducing the oxygen content and cooling the bitumen. The oxidation process affects chemical properties, such as molecule weight and polarity.

Engineers often add a catalyst to increase the speed of the reaction in the oxidation unit. Bitumen properties, such as viscosity, penetration degree, softening point, and reactivity, affect the rate of oxidation reaction. Operational parameters like temperature, pressure, air flow rate, degree of agitation, ratio of air to feed stock, and type of catalyst also affect the rate of oxidation reaction. After sampling and testing the obtained bitumen properties, oxidized bitumen manufacturing stops when parameters like softening point and penetration degree are within the defined range.

You can see a complete process of oxidized bitumen in the video in the link below!

[Oxidized Bitumen Process] ▶

Oxidized Bitumen Application

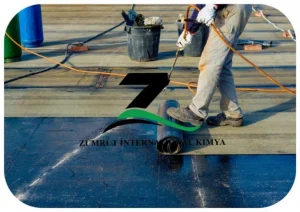

Waterproofing and Roofing

One of the most common uses of oxidized bitumen is in waterproofing systems and roofing materials. Its excellent resistance to water and weather makes it ideal for manufacturing roofing felts, shingles, and other waterproofing membranes. It forms a durable, protective layer that protects buildings from moisture and environmental damages.

Construction and Pavement

In construction, oxidized bitumen has been used for adhesives and sealants in various ways. Examples of where oxidized bitumen is usually applied are joint fillers in concrete pavements, expansion joints in bridges, and lining works in tunnels and reservoirs. Its wear and tear-resistant nature increases the durability of such projects.

Pipe Coating and Corrosion Protection

Owing to the anti-corrosive nature of oxidized bitumen, the material finds extensive applications in coating pipelines, especially those used for water and oil carriage. The material acts as a shield for metal pipes against moisture, chemicals, and environmental elements, thereby considerably increasing the lifecycle of the same.

Industrial Applications

Oxidized Asphalt is applied as an essential ingredient in the manufacturing process of various industrial products, such as paints, lacquers, and adhesives. The capability for blending with polymers and other materials makes it very suitable for the manufacture of high-performance coatings and insulation materials.

Soundproofing and Insulation

Blown Bitumen is dense and elastic, hence it is a good soundproofing and insulating material. It can be used in car manufacturing to build construction, and even in manufacturing materials that provide resistance to vibration.

Cable Coating

In electrical industries, oxidized bitumen is used as insulation and protective coating for cables laid underground. It is used to resist extreme temperature and different environmental conditions to ensure safety and efficiency in electrical systems.

Packaging and Wrapping

Oxidized bitumen serves in the wrapping or packaging of goods in certain industries for the purpose of achieving waterproof or durable covers. In such cases, its strong and water-repellent coating qualities have made it really valued.

In conclusion, Blown Bitumen is a very important commodity in industries ranging from construction to manufacturing. Its unique properties, such as durability, flexibility, and resistance to environmental factors, make it indispensable for innumerable applications.

Oxidized Bitumen Packing

Oxidized bitumen is available in various packings like 20 & 50 kg Kraft paper bags, 25 kg carton box, and 200 kg steel drums. The most expensive packing is the 25 kg mold packing using a removable carton mold with ease of handling at destination.

The 25 kg polyamide bag is heat-resistance and used for quick cooling in water, though it is not possible to remove the bag from the bitumen once the use is made. The 25 kg Kraft bag is recyclable, lined with special layer to prevent sticking and can be loaded either with or without pallets.

Oxidized Bitumen Specifications

Among these bitumen, the most commonly used oxidized or blown bitumen in the market is 85/25, which has a softening point of 85 and penetration grade of 25.

Oxidized bitumen 85/40 is popular in several European nations, including Denmark, Norway, Finland, and Sweden.

| Property | Unit | Typical Value | Test Method |

| Penetration | 0.1 mm (dmm) | 10-20 | ASTM D5 |

| Softening Point | °C | 95-110 | ASTM D36 |

| Density | g/cm³ | 1.00-1.05 | ASTM D70 |

| Viscosity | Pa.s | 200-400 | ASTM D4402 |

| Loss on Heating | % (by weight) | ≤ 0.2 | ASTM D6 |

| Fraass Breaking Point | °C | ≤ -5 | ASTM D3111 |

| Ash Content | % (by weight) | ≤ 0.5 | ASTM D2415 |

| Flash Point | °C | ≥ 250 | ASTM D92 |