General definition of Bitumen 10/20

Penetration Grade Bitumen 10/20 is a type of penetration grade bitumen that is produced by the non-destructive refining of crude oil during petroleum refining. exporting bitumen 10/20 is penetration hard grade and softening between 10 to 20.

bitumen is hard penetration grade bitumen used as paving grade bitumen suitable for road construction and repair also for the production of asphalt pavements with the below technical specification. Bitumen is heavy traffic grade which ensures long-term savings as it allows for a thinner pavement design, which uses up to 30% less asphalt than traditional designs while ensuring extended pavement life. Its penetration grade is between 10 to 20 and its softening point is between 58 to 66°C.

Bitumen Grade 10/20 is a premium brand that is dark brown or black color similar to cement-shape semi-solid or viscous liquid form produced by the non-destructive refining of crude oil during petroleum refining.

Softening point and penetration

Penetration grade bitumen supplied by ATDM is pure petroleum grade bitumen, manufactured from vacuum bottom by passing hot air. The bitumen supplied by ATDM is produced from remain of crude oil after cracking and removing hydrocarbon. Penetration grade bitumen 10/20 has penetration between 10~20 desi-millimeter and softening point between 58 ~ 66 c. The penetration grade it has a thermoplastic property which is like as synthetic resin material which gets softer with heating and hardens when cooled. This grade of the bitumen 10/20 has very strong viscosity compare to other grades.

Application of Bitumen 10/20

This grade of bitumen is also mainly used in the manufacture of hot mix asphalt. also, Bitumen is suitable for road construction and repair for asphalt pavements with superior properties. Bitumen is used for hot mixed asphalt because of the properties of very strong viscosity compared to other grade.

Guaranty of blown asphalt

Quality of bitumen penetration grade with the arrangement of the international inspector to check the quality and quantity of the bitumen penetration grade during the loading to the vessel and controlling the production by QC by batch test report before shipping.

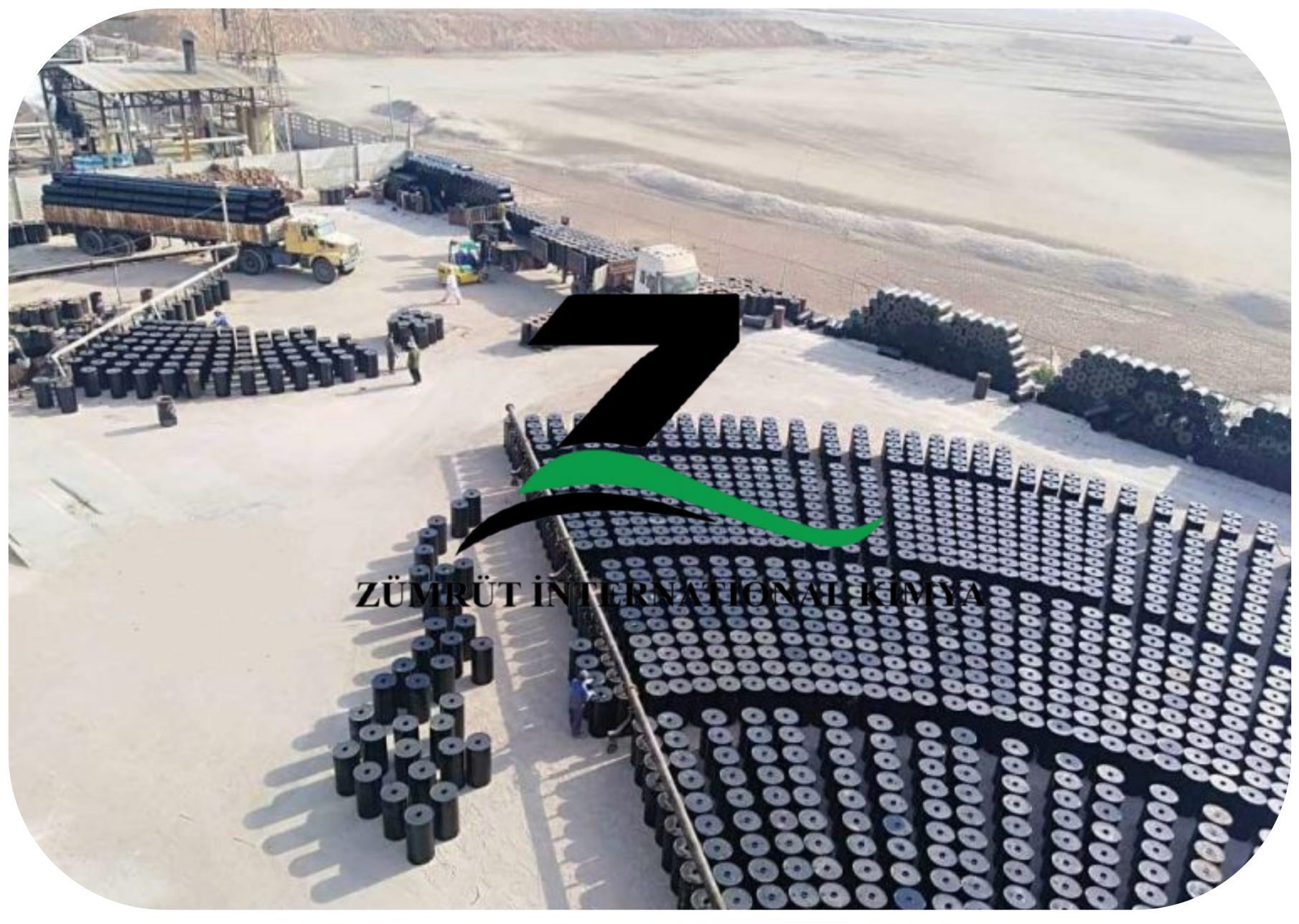

Packing of Bitumen Penetration Grade

Bitumen’s packaging is a real concern especially if it’s meant to be exported, the better and safer packaging, guarantees the better delivery of the cargo. There are several different ways to package the bitumen which can vary depending on the tonnage, type, and grade of the bitumen- as mentioned before, different grades of bitumen have different levels of stiffness and viscosity- so the grade also plays an important role in choosing a suitable packaging. Bitumen grade 10/20 is commonly packed in new steel drums, 150, 180 & 220 Kg barrels and Jumbo Bags or 300 Kg Bitubag.

Properties of Bitumen 10/20

It is derived from the non-destructive refining of crude oil, ensuring premium quality and longevity. With a penetration grade of 10~20 desi-millimeter and a softening point of 58 ~ 66°C, Bitumen 10/20 thermoplastic and ideal for various applications.

Specification

| Bitumen 10/20 | Test method | Unit | Specification |

|---|---|---|---|

| Specific gravity @ 25°c | ASTM D70 | Kg/cm3 | 1.01/1.06 |

| Penetration @ 25°c | ASTM D5 | Mm/10 | 10/20 |

| Softening point °c | ASTM D36 | °C | 58/66 |

| Ductility @25 °c | ASTM D113 | Cm | 100 min |

| Loss on heating(wt) % | ASTM D6 | wt % | 0.2 max |

| Drop in penetration after heating % | ASTM D5-D6 | % | 20 max |

| Flashpoint c | ASTM D92 | °C | 250 min |

| Solubility is CS2(wt) % | ASTM D4 | wt % | 99.5 max |

| Spot test | A.a.s.h.o.t102 | ----- | Negative |