Description of Oxidized Bitumen 85/40

Oxidized bitumen 85/40 (in other words, oxidized bitumen 85/40, blown bitumen 85/40) is Semi Solid grade of pure petroleum bitumen manufactured by air-blowing through an asphalt flux. Special physical properties of its grade can be used in different applications in the construction business. Oxidized bitumen 85/40 is based on petroleum bitumen which is made by oxidized asphalt 60/70 by hot air.

The numbers relate to the midpoint of the material’s softening point and penetration respectively. The softening point value is the degrees Centigrade measured by the Ring and Ball method as determined by ASTM D36. The penetration value is in 1/10 mm as determined by IP49 or ASTM D5.

The quality of blown bitumen 85/40 with the arrangement of the international inspector to check the quality and quantity of the bitumen 85/40 during the loading to the vessel and controlling the production by QC by batch test report before shipping. Oxidized bitumen has a higher softening point than viscosity grade and penetration bitumen. Consequently, oxidized bitumen is less susceptible than penetration bitumen and viscosity bitumen to temperature changes.

Uses of Oxidized Bitumen 85/40

This bitumen is mostly used in industry, such as roof insulation, flooring, industrial mastic, pipe coating, and paints. Specification of Oxidized bitumen is categorized based on softening points and penetration rate. Also, Oxidised Bitumen 85/40 using as raw material for bitumen coat, roofing, insulation, and isolation bitumen membrane sheet.

Oxidized bitumen 85/40 is normally applied in chemical, fuel, lacquers, varnishes, paint paper-pulp-board, textile processing, road construction, pavement, civil works, roofing, construction industries; sealing and insulating buildings, adhesive, crack seal and repairmen, construction materials additive, dust-binding, insulating and impregnating agent, make rubber and plastic products.

also used in asphalt-based paints for corrosion protection of metals, inlining public works structures, adhesives in electrical laminates, the base for synthetic turf.

Application of Blown Bitumen 85/40

his kind of bitumen is suitable to be used in the chemical, raw material for bitumen coat, paper-pulp-board, textile processing, pavement, crack seal and repairmen, civil works, bitumen coat for piping, roofing, construction industries; sealing and insulating buildings, adhesive, construction materials additive, road construction, dust-binding, insulating and impregnating agent, isolation bitumen membrane sheet, make rubber and plastic products.

typical uses for Bitumen 85/40 include roofing, pipe coating, hydraulic applications, 85/40 is mainly using in paint manufacturing and coating in hot area.

Storage and Handling of Bitumen 85/40

Oxidized bitumen has 10 years of validity with multi-time heating and cooling. Please refer to MSDS for more information.

Health & safety of blown asphalt 85/40

Workers should wear protective masks, gloves, and goggles during application. The asphalt can be removed from equipment and tools with kerosene or gasoline.

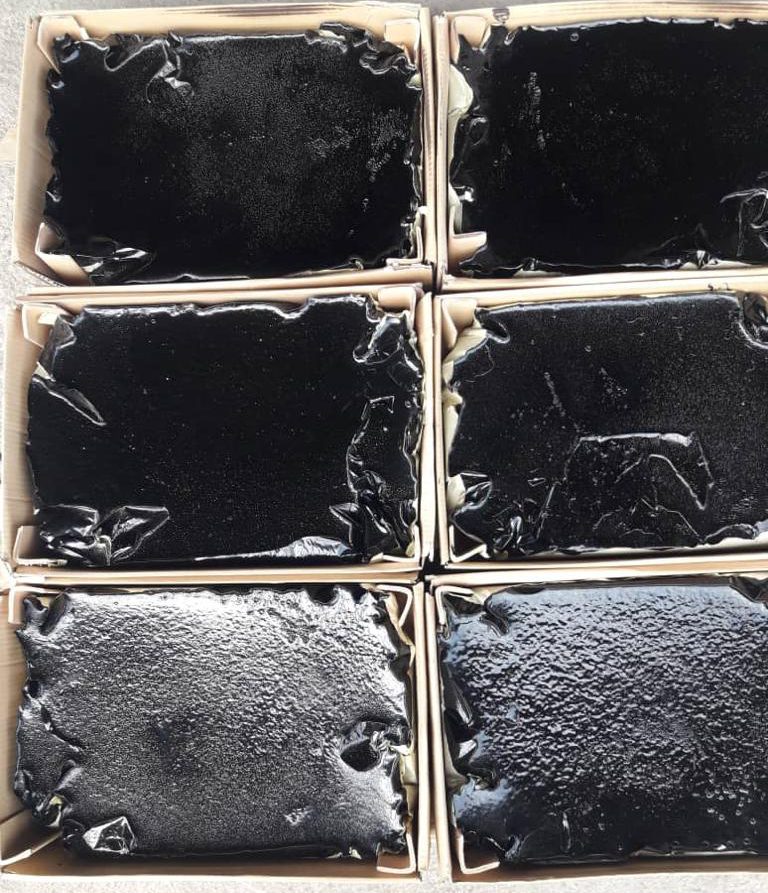

Packing of Oxidized Bitumen 85/40

• Meltable Polyamide Bags (20KG) (25 Kg)

• Carton Box (20KG) (25 Kg) (40kg)

• Kraft Bags (20KG) (25 Kg) (40kg)

• Blocks (20KG) (25 Kg) (40kg)

• Drums (20KG) (25 Kg)

Other kinds of packing and Size are welcome from clients.

Specification of Oxidized Bitumen 85/40

| Oxidized Bitumen 85/40 | Specification | Test Method |

| Specific gravity@25/25 ˚C | 1.05 approx | D-70 |

| Penetration@25 ˚C | 35-45 | D-5 |

| Softening point ˚C | 80-90 | D-36 |

| Ductility@25 ˚C | 3 | D-113 |

| Loss on heating (wt)% | 0.5 | D-6 |

| Flash point ˚C | 230 min | D-92 |

| Solubility in CS2 (wt)% | 99 min | D-4 |