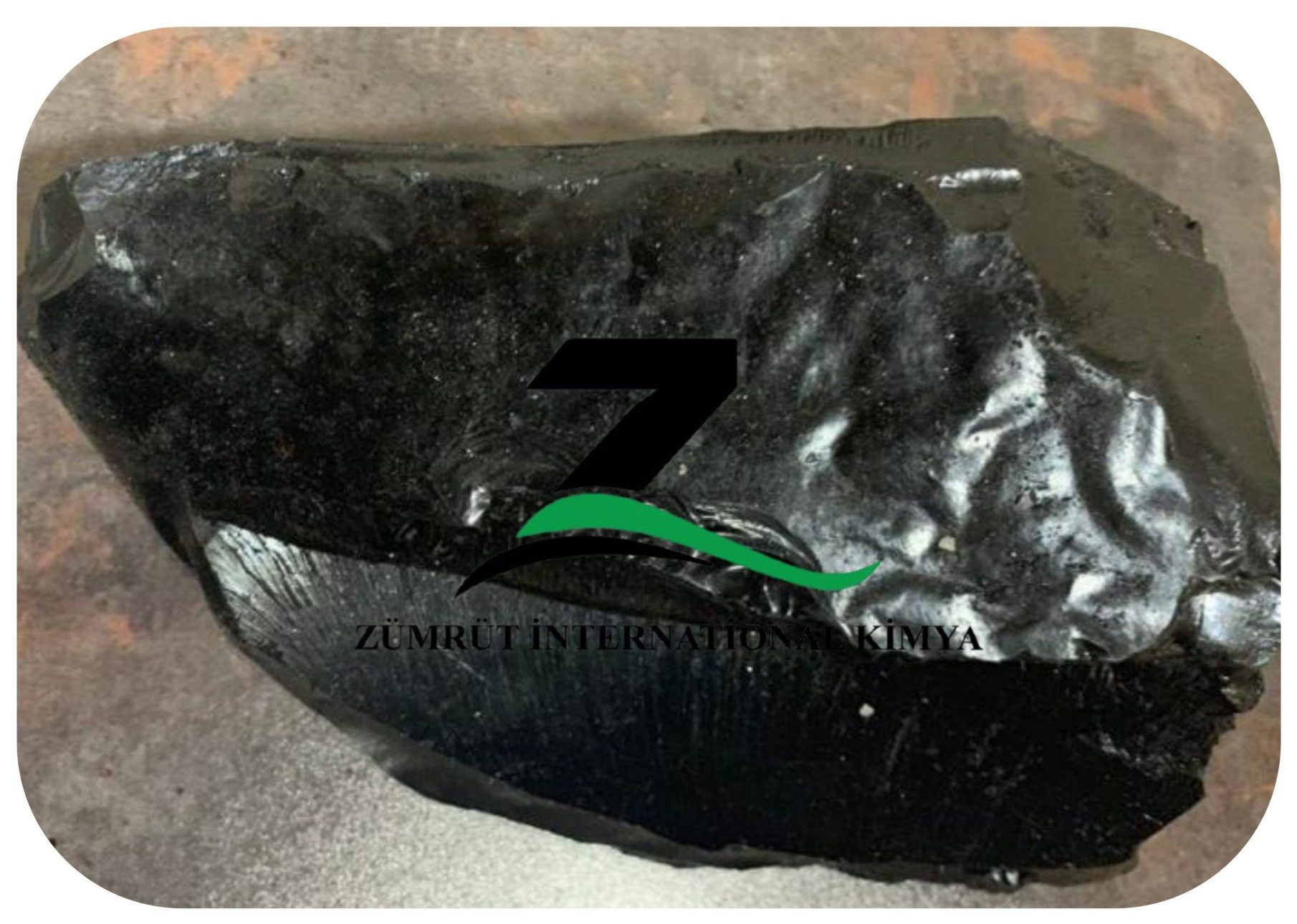

Definition of Oxidized Bitumen 75/35

Oxidized Bitumen 75/35 is an oxidized Asphalt produced by oxidizing a selected petroleum asphalts without adding the catalyst. Oxidized Bitumen 75/35 has high softening point, high flash point and it is highly stable during melting.

As said before, Bitumen 75/35 is based on petroleum bitumen which is made by Blowing Bitumen 60/70 by very hot air. In addition, the numbers relate to the midpoint of the material’s softening point and penetration respectively.

The softening point value measured by Ring and Ball method as determined by ASTM D36. Also, the penetration value is in 1/10 mm as determined by IP49 or ASTM- D5. Oxidized bitumen has a higher softening point than viscosity grade and penetration bitumen. Consequently, oxidized bitumen is less susceptible than penetration bitumen and viscosity bitumen to temperature changes.

Our sales team is committed who understands your requirements due to many years of experience in supplying the bitumen products. If you are more interested in product information or need to place an order contact or inquire our Sales team.

Application of Oxidized Bitumen 75/35

- Roofing and waterproofing systems

- Pipe coating and corrosion protection

- Crack seal and pavement repair

- Bitumen coating for civil and industrial works

- Hydraulic insulation and sealing in construction

- Raw material for bitumen-based paints and coatings

- Dust-binding agent for unpaved roads

- Impregnating and insulating agent for buildings

- Production of isolation membrane sheets

- Additive in construction materials

- Adhesive in industrial applications

- Paper, pulp, and board treatment

- Textile processing industry

- Rubber and plastic product manufacturing

- Coating in hot climate zones

Oxidized Bitumen 75/35 Vs.75/25

75/25 and 75/35 Oxidized Bitumen are semi-solid varieties used primarily for waterproofing, pipe coating, and construction purposes involving insulation. Both have a similar softening point of around 75 °C but differ primarily with respect to penetration and flexibility. The penetration of Bitumen 75/25 is relatively lower (around 20–25 dmm), which makes it stiff and suitable for uses requiring some thermal resistance as well as durability in warm temperatures.

On the other hand, Oxidized Bitumen 75/35 has higher penetration (around 30–40 dmm), softer consistency, and more elasticity. It is thus well suited for applications involving movement or bending, such as pipe wrapping or sealing joints where the weather is cooler or temperate. They are both produced by air-blowing base bitumen and conform to ASTM standards but are applied based on the specific mechanical and environmental demands of the project.

|

Oxidized Bitumen 75/25 is a semi-solid consistence bitumen product manufactured through air-blowing of pure petroleum bitumen or flux asphalt. Through air-blowing, physical strength of the material is increased to be useful for various purposes of building. It is stabilized based on petroleum bitumen 60/70 and oxidized through hot air 75/25 is its name with its mid-value range of softening point as well as penetration. ASTM D36 standard ring and ball method fixes the softening point, while a reading of penetration is made at 1/10 mm based on ASTM D5 or IP 49. |

Storage and Handling

Blown asphalt 75/35 is best up to 10 years from the day it was manufactured. It is suggested for higher time of warehouse keeping to keep the bitumen under shelter and out of the rain and sun shine.

Health & Safety

Workers must wear protective goggles, gloves, and masks when working with asphalt to prevent exposure to fumes, heat, and chemical irritation. Ventilation is also required to minimize the hazards of inhalation. Tools and equipment can be washed with gasoline or kerosene following use, since these solvents readily dissolve asphalt residue. These solvents should, however, be carefully handled away from open flames and in well-ventilated areas to prevent hazard.

Packing of Oxidized Bitumen 75/35

The packing of 25kg mold is more expensive than other weights, due to the strong carton mold it contains. This will ensure that shipment of the molds can be easy and when it gets to destination, removal of it is done with ease. High heat resistance of polyamide bag 25kg makes cooling pretty faster by dipping into water. But is only a single application solution, since the used bitumen could not be separated from the polyamide material. Whereas, the 25kg craft bag is the ecological solution which could be recycled along with an internal specific coating for avoiding adhesion of the bitumen on packaging. Such kind of bags may also be applied without palletizing as well according to customer preferences.

Specification

| Bitumen 75/35 | Test method | Unit | Specification |

|---|---|---|---|

| Specific gravity @25/25 C | ASTM D70 | (Kg/m3) | 1.05 approx. |

| Penetration @ 25°c | ASTM D5 | mm/10 | 30/40 |

| Softening point °c | ASTM D36 | °C | 70/80 |

| Loss on heating(wt) % | ASTM D6 | Wt. % | 0.2 max |

| Flashpoint c | ASTM D92 | °C | 250 min |

| Solubility is CS2(wt) % | ASTM D4 | Wt. % | 99.5 max |

| Spot test | A.A.S.H.T.O 102 | — | Negative |

Why Choose Oxidized Bitumen 75/35?

Oxidized Bitumen 75/35 is a reliable and efficient industrial solution with sufficient heat resistance and strong adhesive. With a softening point of approximately 75°C, it performs well in waterproofing, thermal insulation, and formulating industrial adhesives.

Thanks to its higher durability, stable performance in various climates, and more environmentally friendly production process, Bitumen 75/35 offers a long-term solution for diverse construction and infrastructure projects, thus being a rational and sustainable material choice.

FAQs

What are the benefits of using Oxidized Bitumen 75/35?

Oxidized Bitumen 75/35 offers excellent adhesion, waterproofing, and thermal stability, making it ideal for construction and industrial projects that demand long-lasting, high-performance materials.

What safety measures should be taken when handling Oxidized Bitumen 75/35?

Proper personal protective equipment (PPE), including gloves, goggles, and respiratory protection, should be used to avoid direct contact with the material and inhalation of fumes. The work area should also be well-ventilated.

Is Oxidized Bitumen 75/35 suitable for use in cold climates?

While it can be used in moderately cold climates, Oxidized Bitumen 75/35 is more suitable for moderate temperatures and may have an increased viscosity in extreme cold conditions.

Is Oxidized Bitumen 75/35 environmentally friendly?

Oxidized Bitumen 75/35 is generally safe for use when handled correctly. Proper disposal and adherence to environmental guidelines are necessary to minimize the impact on the environment.

How long does Oxidized Bitumen 75/35 last?

When stored correctly, Oxidized Bitumen 75/35 has a shelf life of up to 10 years, retaining its quality and pe

formance during this period.