There have been several Test of Bitumen established to assess the qualities of bitumen, each with distinct characteristics useful to a certain application, primarily on roads. In general, there are 10 tests for bitumen, which we will briefly introduce below:

1. Penetration Test:

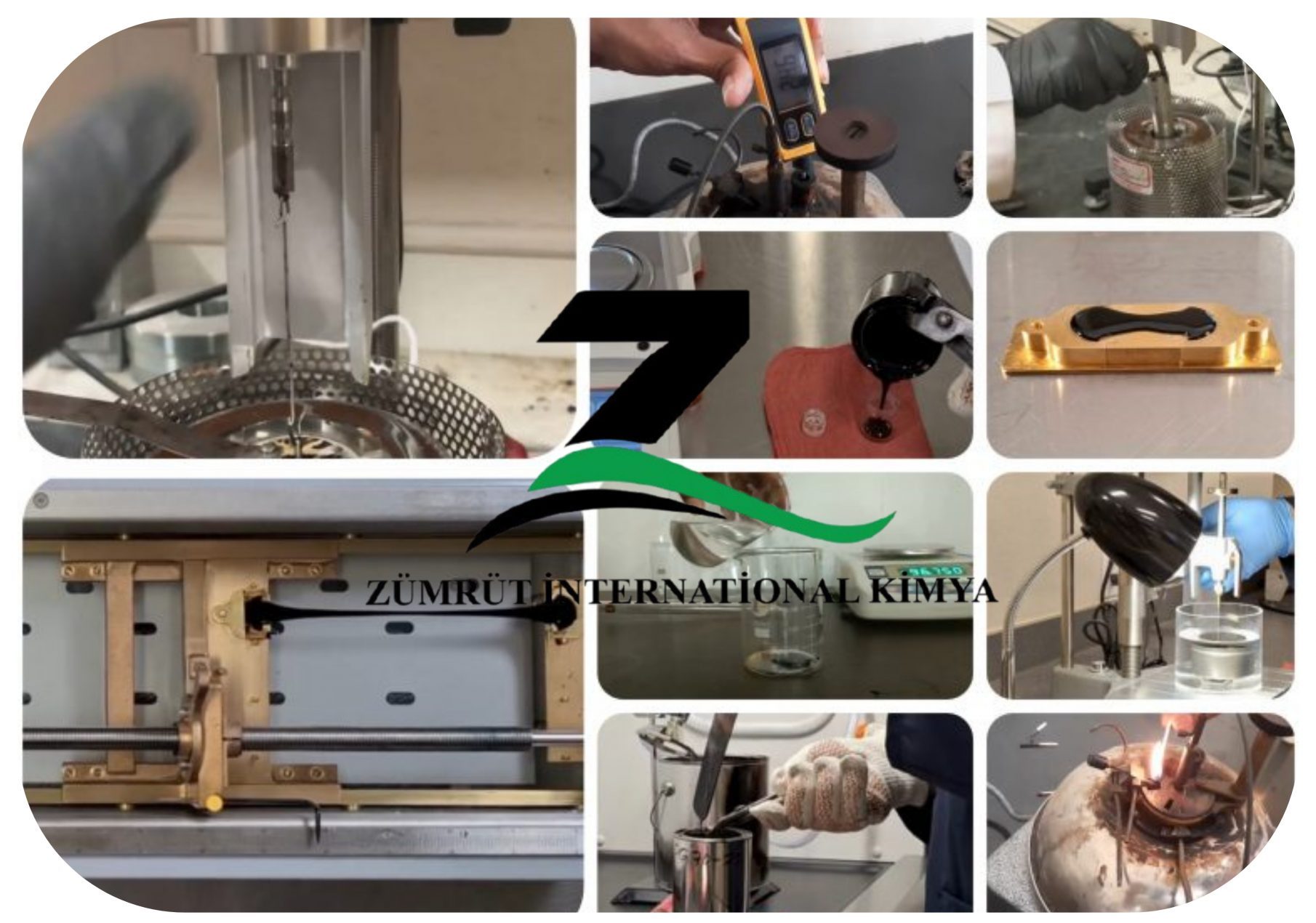

The bitumen penetration test is a crucial method used to assess the consistency and hardness of bitumen.

It involves driving a standard needle into a sample of bitumen under specific conditions of load, time, and temperature.

The depth to which the needle penetrates the bitumen is measured and indicates its softness or hardness.

This test helps classify bitumen and determines its suitability for different applications and climates.

2. Softening Point Test:

The consistency of a bitumen can be measured by determining its softening point.

This test involves placing a steel ball on a bitumen sample in a brass ring suspended in a water or glycerin bath.

Water is used for bitumen with a softening point of 80°C or below, while glycerin is used for those greater than 80°C. The bath temperature is raised at 5°C per minute, and the bitumen softens and deforms slowly with the ball.

The water temperature is recorded when the bitumen and steel ball touch a base plate 25mm below the ring. The test is repeated if the difference exceeds 1.0°C, and the reported temperature is the softening point of the bitumen.

The ASTM version of the softening point test does not stir the bath, while the IP version stirs the water or glycerin. ASTM results are generally 1.5°C higher than IP or BS method11591.

3. Ductility Test:

Ductility is a crucial property of bitumen, indicating its ability to withstand road deflections, reducing cracking probability and increasing asphalt life span.

It is measured through a ductility test, where bitumen is poured into a tester and pulled at a speed below its softening point. The test measures the length of bitumen stretched before tearing apart.

Ductility typically ranges from 5 cm to over 100 cm, with an acceptable value of over 50 cm. This test is essential for road construction and can measure the cohesive strength of bituminous products like oxidized and cutback bitumen.

4. Viscosity Test:

Finding out how fluid bitumen is requires running it through a viscosity test. The fluidity of bitumen refers to its ability to spread across the pavement area. Asphalt with aggregate added makes it as smooth as glass because of its lower viscosity.

Follow the instructions in IS code 1206 to use a viscometer to measure the bitumen’s viscosity. The time it takes 50 ml of bitumen to pass through the orifice cup is a measure of its viscosity.

5. Specific Gravity:

The Specific Gravity Test is a method used to determine the specific gravity of bitumen, which is determined by filling a pycnometer with a known volume of bitumen.

The weight of the bitumen is then divided by the weight of an equal volume of water to calculate its specific gravity.

However, this test has limitations, as it doesn’t provide information on the chemical composition or performance characteristics of the bitumen, and may be influenced by factors like temperature, air bubbles, and contamination. Therefore, it should be used in conjunction with other tests.

6. Solubility:

The solubility test is used to determine the amount of coke or mineral matter in bitumen. Bitumen is defined as being soluble in trichloroethylene, which is rarely used due to special precautions. Other aggressive solvents include carbon disulphide, benzene, dichloromethane, trichloroethane, trichloroethylene, and toluene.

Trichloroethylene is commonly used, but due to halogenated hydrocarbon toxicity concerns, it is replaced with aromatic hydrocarbons like toluene or xylene.

The sample is dissolved in solvent, filtered through a layer of powdered glass, washed, dried, and weighed. Modified bitumen may require modified methods or solvent mixtures to ensure the total dissolution of both bitumen and polymer additive.

7. Flash and Fire Point Test:

The Flash and Fire point test on bitumen is crucial for determining safe mixing and application temperatures of specific bitumen grades. This is because volatile vapors in bituminous materials can catch fire easily at higher temperatures, causing flashes at one point and potentially igniting and burning if further exposed to heat.

Catching fire is dangerous during mixing and application of bitumen, making it essential to identify safe temperature values for mixing and application.

The Flash point test measures the lowest temperature at which vapor burns in the presence of an ignition source with an instant flame. The Fire point test measures the temperature higher than the flash point, where the flame lasts more than 5 seconds.

The National Fire Protection Association (NFPA) defines flammable liquids with a flash point below 100°F (37.2°C) and combustible liquids with a flash point equal to or above 100°F (37.2°C).

8. Loss on Heating Test:

The loss on heating test is a method used to control the volatility of bitumen and determine its potential ‘cut’ by low molecular weight flux. It involves heating a sample of bitumen in a film at 163°C for five hours, determining the loss in weight.

The Thin Film Oven Test (TFOT) assesses the susceptibility to hardening and loss of volatiles. A third test, the Rolling Thin Film Oven Test (RTFOT), is introduced to assess the effect of heat and air on a moving bitumen film.

These tests measure the properties of the resultant bitumen compared to the original, allowing for measurements of penetration or viscosity changes.

The first test is widely used for specification purposes, while the second is used in the UK to assess the effects of manufacturing processes on penetration grade bitumen. However, no tests have been shown to accurately predict the effects of hardening for oxidised bitumen due to low temperatures and skin formation on samples.

9. Spot Test:

The spot test is a method used to determine the quality of bitumen. It involves dissolving a 2g bitumen sample in a solvent and dropping a small drop onto filter paper. If the solution appears completely brown, it indicates good quality. If it is brown with a black center, it indicates damage from overheating in a refinery. This test is applicable to extracted bitumen from crude oil, but should not be used with natural bitumen insoluble in xylene. High-tech refineries ensure proper heating, preventing damage to bitumen.

10. Float Test:

The Float Test measures the time it takes for bitumen to float to the top of boiling water, indicating its consistency and temperature susceptibility.

These, along with other tests such as the Drop in Penetration After Heating Test and the Complex Modulus Test, give useful information about the properties of bitumen, which enables engineers to choose the right grade for any particular application and assure the quality and performance of bituminous pavements.