PG Bitumen 70-16 Description

The performance grade PG 70-16 bitumen is developed for those regions that have a temperate climatic condition, and the temperature and traffic load show mid-intensity variation. The bitumen shall exhibit balanced performance through the combined flexibility and stiffness for long-lasting pavement durability. The high elasticity of this bitumen grade prevents the pavement from cracking at low temperatures, while high resistance to rutting gives stability to the pavement under moderate volumes of traffic and high temperatures.

Due to the specific properties, PG 70-16 is recommended for road constructions in zones that do not show extreme climatic conditions but have seasonal temperature differences. This bitumen grade is ideal for pavements with medium-intensity traffic that comes fairly regularly, such as in city roads, secondary highways, and commercial places.

Over time, PG 70-16 bitumen roads show excellent resistance to consolidations due to both environmental stress and traffic load in good time. Its ability to retain structural integrity with minimum deformation under thermal and mechanical stresses makes it very reliable for long-term service performances in the infrastructure projects.

Application of PG Bitumen 70-16

PG 70-16 bitumen is a versatile material widely used in road construction and paving projects, particularly in regions with moderate climates and medium-intensity traffic conditions. Below are the major areas of its use:

Roads and Streets of Urban Areas

PG 70-16 is usually used in urban roadway construction that receives normal traffic without being subjected to extreme weather conditions. Its balanced flexibility and stiffness will last long and hence reduce the maintenance cost of city infrastructure.

Secondary Highways

This grade is suitable for secondary highways where traffic volumes and loads are moderate. Its ability to resist rutting under elevated temperatures and cracking at lower temperatures ensures smooth and stable driving conditions over time.

Parking Lots and Commercial Zones

The resistance to deformation, along with PG 70-16’s durability and moderate cost, makes the mixture suitable for parking lots and commercial areas where vehicles exert frequent but moderate loads. The mixture helps the surface to remain even under repeated stress.

Climate-Specific Projects

PG 70-16 will be the most suitable for areas that have an average temperature and are not very fluctuating. In regions with less seasonal variation, it can serve better, keeping the pavements intact from very hot summers to mild winters.

Residential and Suburban Areas

Being rather economical, PG 70-16 is found on residential streets and in suburban subdivisions to handle the moderate conditions of wear and tear by local traffic.

performance of current pavement by improving its status. Compatibility with an extremely variable supply of aggregates with good durability against moderate conditions explains this PG usage particularly in rehabilitation efforts.

PG Bitumen 70-16 vs PG Bitumen 76-16

The key difference between PG Bitumen 70-16 and PG Bitumen 76-16 lies in their high-temperature performance and rutting resistance. Both are resistant to temperatures of -16°C without cracking and therefore can be applied in cold climates. Nevertheless, PG 76-16 is more heat-resistant with a maximum of 76°C, while PG 70-16’s limit is 70°C. This makes PG 76-16 better adapted to warm climates or high-volume roads where deformation resistance is required, and PG 70-16 best where moderate summer temperatures and cold winters are the rule.

International Standards and Global Comparisons

PG Bitumen 70-16 meets international standards such as ASTM and AASHTO specifications to ensure high performance and reliability in international markets. It is compared with other performance grades used in different climatic conditions. For example:

PG 76-10: More suitable for hot climates with heavy traffic due to its.

The nations experiencing moderate winters and hot summers, such as the North American, European, and Asian regions, prefer PG 70-16 because of its balanced properties.

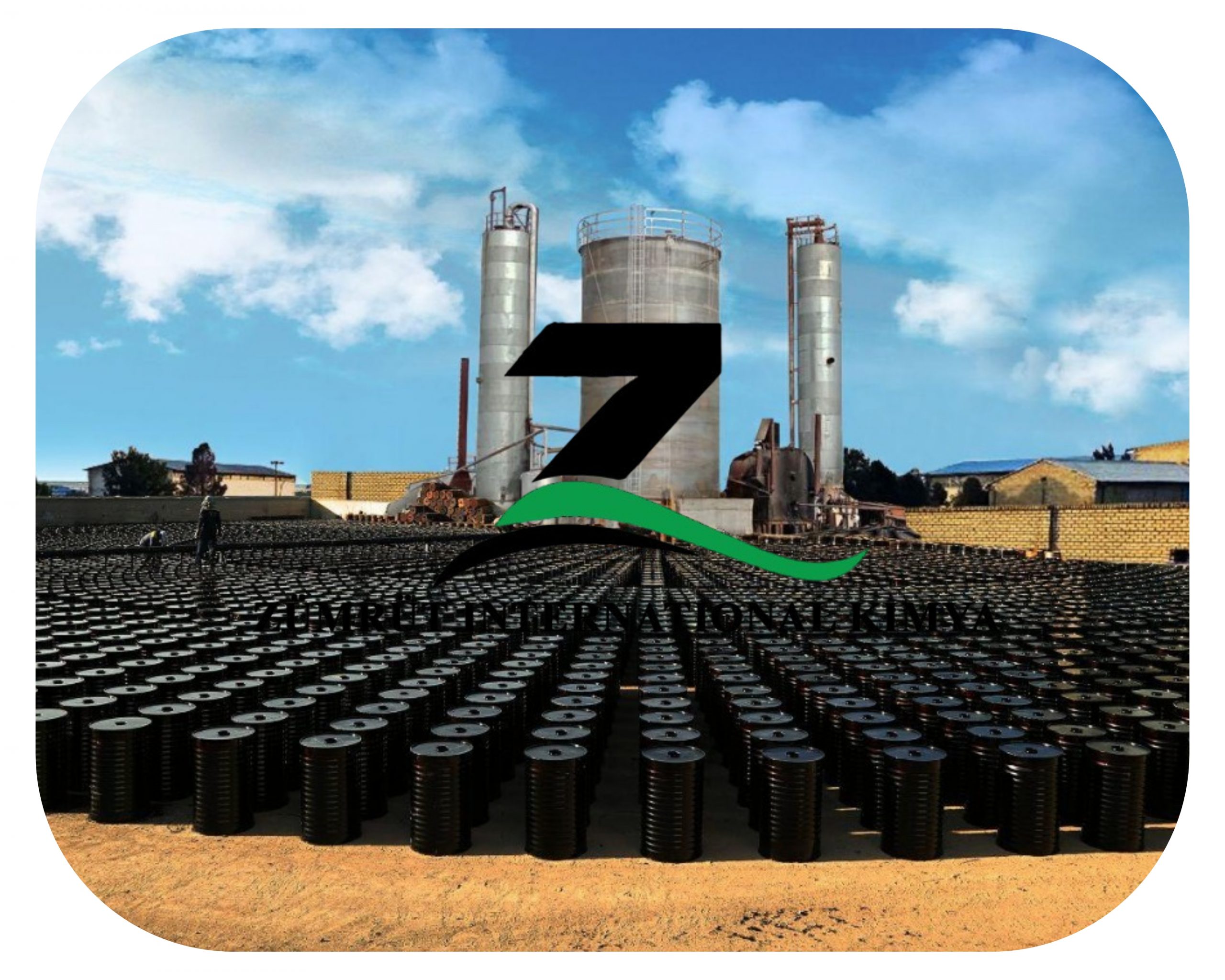

Packing of PG Bitumen 70-16

Performance Grade PG 70-16 bitumen is available in various packing options to suit diverse needs, including bulk transport in insulated tankers for large-scale projects, steel drums (150-220 liters) for medium-sized projects and export purposes, and eco-friendly polybags (25-50 kg) for smaller, portable applications.

Bulk transport ensures that the material is cost-effective and its optimum state is maintained during transportation, while drums offer convenience in storage and handling. These carry lightweight and spill-resistant solutions for remote or smaller projects. Versatile packaging methods ensure safe deliveries and preservation of bitumen quality across different project scales.

Specification

| Specification | Unit | Value | Method |

|---|---|---|---|

| Average 7-Day Maximum Pavement Design Temperature | °C | < 70 | – |

| Minimum Pavement Design Temperature | °C | > -16 | – |

| Flash Point Temperature | °C | Min230 | AASHTO T48 |

| Viscosity Maximum 3 Pa.s, Test Temperature | °C | 135 | AASHTO T316 |

| Dynamic Shear G*/sin Minimum 1 KPa Test Temperature | °C | 70 | AASHTO T315 |

| Rolling Thin Film Oven Test (AASHTO T240) | |||

| Mass Change | % | Max1.00 | – |

| Dynamic Shear G*/sin Minimum 2.2 KPa Test Temperature, @10 rad/s | °C | 70 | AASHTO T315 |

| Pressure Aging Vessel (PAV) Test (AASHTO R28) | |||

| PAV Aging Temperature | °C | 100 (110) | AASHTO R28 |

| Dynamic Shear G*/sin Maximum 5000 KPa Test Temperature, @10 rad/s | °C | 31 | AASHTO T315 |

| Creep Stiffiness S Maximum 300 Mpa M-Value Minimum 0.300 Test Temp,@60s | °C | -6 | AASHTO T313 |

| Direct Tension Failure Strain Minimum 1 % Test Temp@1mm/min, | °C | -6 | AASHTO T314 |

| Critical Low Cracking Temperature Critical Cracking Determined by PP42 Test Temp | – | -6 | AASHTO PP42 |