Description of MC

Medium Curing (MC)

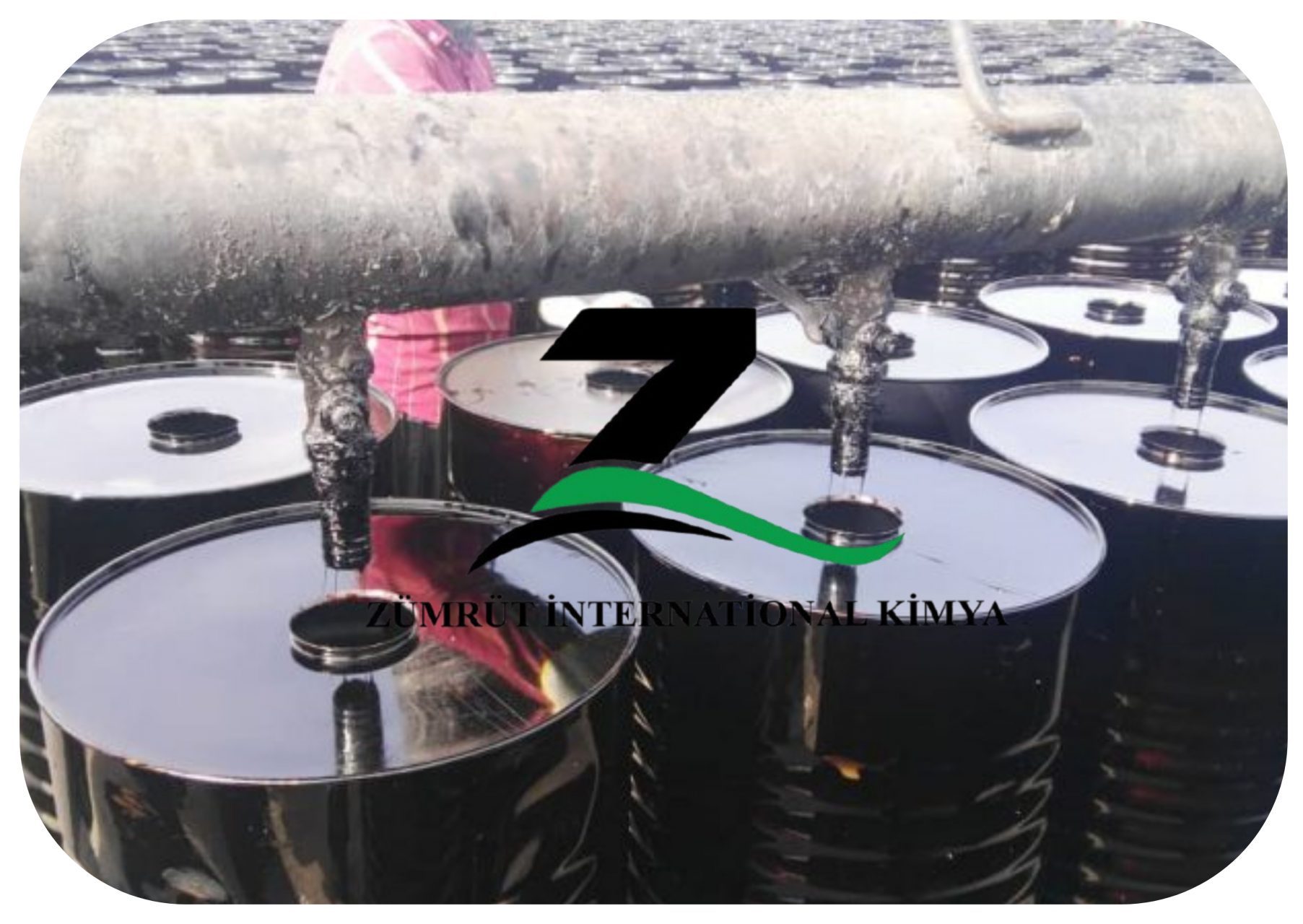

Medium Curing cutback bitumen is a solvent bitumen blend with a moderately volatile solvent, typically kerosene. It has widespread usage in flexible pavements for surface dressing, prime coating, tack coating, and cold mix asphalt. It possesses a medium evaporation rate with a balance between setting time and workability, which makes it especially suitable for use where a longer handling time is needed.

What’s Special About MC Cutback Bitumen?

The property that identifies MC cutback bitumen is the application of kerosene, which possesses a medium evaporation rate compared to lighter solvents like gasoline (used in RC grades). Such medium volatility makes the bitumen workable for an extended period before it cures, hence is particularly appropriate for cold mix stockpile preparation and maintenance operations under various climatic conditions.

Fluidity of MC cutback bitumen is directly dependent on the ratio of kerosene to asphalt. Manufacturers can vary this blend to make the product’s viscosity suitable for a variety of roadwork applications.

Standard Grades of MC Cutback Bitumen

MC cutbacks are available in the following grades, which are defined in terms of viscosity:

Each is a unique combination of fluidity and curing time, allowing engineers to select the proper product for specific project conditions.

Uses of Medium Curing Cutback Bitumen

Cold Mix Asphalt

MC bitumen is a significant cold mix asphalt binder that is extensively utilized in rural or cold climate conditions where hot mix asphalt cannot be utilized. The moderate setting time of MC bitumen makes the mixture easy to handle for storage and transportation.

Prime Coating

MC cutback bitumen is used on unbound granular bases before the surfacing courses of asphalt are applied. The prime coat is used to stabilize the base and improve adhesion between the base and the surfacing course.

Patching of Potholes and Pavement

Because of its extended workability, MC bitumen is used to patch potholes and patch up road damaged sections, especially in areas where quick access to hot mix plants is not attainable.

Surface Dressing

Utilized as a binder to bind aggregates together, MC cutback bitumen improves skid resistance and prolongs pavement surface life.

Environmental Considerations

After application, the kerosene solvent will evaporate, leaving a tough bitumen film. Nevertheless, because petroleum solvents are used, there is need to have proper handling, storage, and environmental safety measures in place to guarantee secure use.

Summary

Medium Curing Cutback Bitumen offers the ideal blend of workability, flexibility, and performance. With its low evaporation rate, it is an all-purpose product that can carry out numerous tasks in construction and maintenance processes of roads. Whether used in cold mix asphalt or prime coats, MC bitumen is a core element of modern-day infrastructure projects.