What is Bitumen VG10?

Bitumen VG10 is a viscosity grade bitumen, a hard hydrocarbon product derived from crude oil by fractional distillation. Because it has low viscosity, it is ideal for application in road construction at low temperatures, giving roadways flexibility to prevent cracks and ugliness.

It being a thermoplastic material, VG10 becomes hard when it is cold and soft when hot, giving consistent performance over a broad temperature range. Here in this guide, we talk about VG10’s features, applications, and why it is one of the best in paving work.

Uses of Bitumen VG10

Bitumen VG10, a viscosity-grade bitumen, is an extremely flexible product of very low viscosity and high elasticity, so it’s the first choice for road construction and road repair, particularly in cold climates. Its consistency across a broad temperature range (e.g., at 40°C) makes it an ideal replacement for the outdated 80/100 penetration-grade bitumen. Below, we consider Bitumen VG10’s primary applications, describing how it is used and why it’s effective.

Surface Dressing

VG10 bitumen is widely used in surface dressing, a cost-effective technique of road preservation in which a thin layer of bitumen is sprayed onto a road surface and coated with aggregate (gravel or small pebbles). This creates a hard, skid-resistant covering that protects the pavement from water damage and wear. The low viscosity of VG10 enables it to spray well and provides good adhesion to aggregates due to even application. It is especially effective in cold conditions since the ability of VG10 to resist cracking is curbed by temperature fluctuations.

Hot Mix Asphalt (HMA)

VG10 is a significant ingredient in the production of hot mix asphalt, a mixture and heating of bitumen and aggregates to produce a smooth, long-wearing road surface. The low viscosity of VG10 helps it bond effectively to aggregates to create a hard and long-lasting bond that can withstand traffic stress and stress of the weather. It’s typically used to seal roads, highways, and airport runways in mild to cold climatic conditions, where its elasticity maintains pavement strength.

Production of Emulsion and Modified Bitumen

Bitumen VG10 serves as a raw material for the manufacture of emulsion bitumen (bitumen, water, and emulsifying agents blend) and modified bitumen (polymers- or additives-enriched bitumen). Emulsion bitumen is used in cold mix asphalt and tack coats applications, while modified bitumen is used for long-lasting performance on heavy traffic roads. The properties of VG10 render it an ideal starting raw material for these cutting-edge products because it delivers workability and performance in balance.

Tack Coat Application

VG10 is used as a tack coat, which is a thin bitumen application on an existing road surface to bond new layers of asphalt. Its viscosity ensures strong bonding between layers, preventing slippage and strengthening the road structure. VG10’s fluidity ensures easy application smoothly, ensuring good bonding.

Why Bitumen VG10 Excels

Bitumen VG10’s low viscosity and thermoplastic nature also render it highly suitable for cold climatic conditions, where it will be flexible to resist cracking and is capable of withstanding changes in temperature. Its ease of application in spraying and mixing operations reduces construction time and cost. Additionally, VG10 compatibility with other paving systems and use as a base for specialty bitumen products render it a go-to material for road construction and maintenance contractors and engineers.

For further information about how VG10 can meet your project needs, contact a trusted bitumen distributor to verify specifications and availability.

Bitumen VG10 vs. VG20

| Feature | Bitumen VG10 | Bitumen VG20 |

|---|---|---|

| Viscosity | Lower viscosity, more fluid | Higher viscosity, less fluid |

| Climate Suitability | Moderate to cold climates | Cold climates and high altitudes |

| Applications | Spray sealing, thin asphalt layers, hot mix | Wearing/base courses, heavy-duty roads |

| Durability | Flexible, prevents cracking | More resistant to extreme conditions |

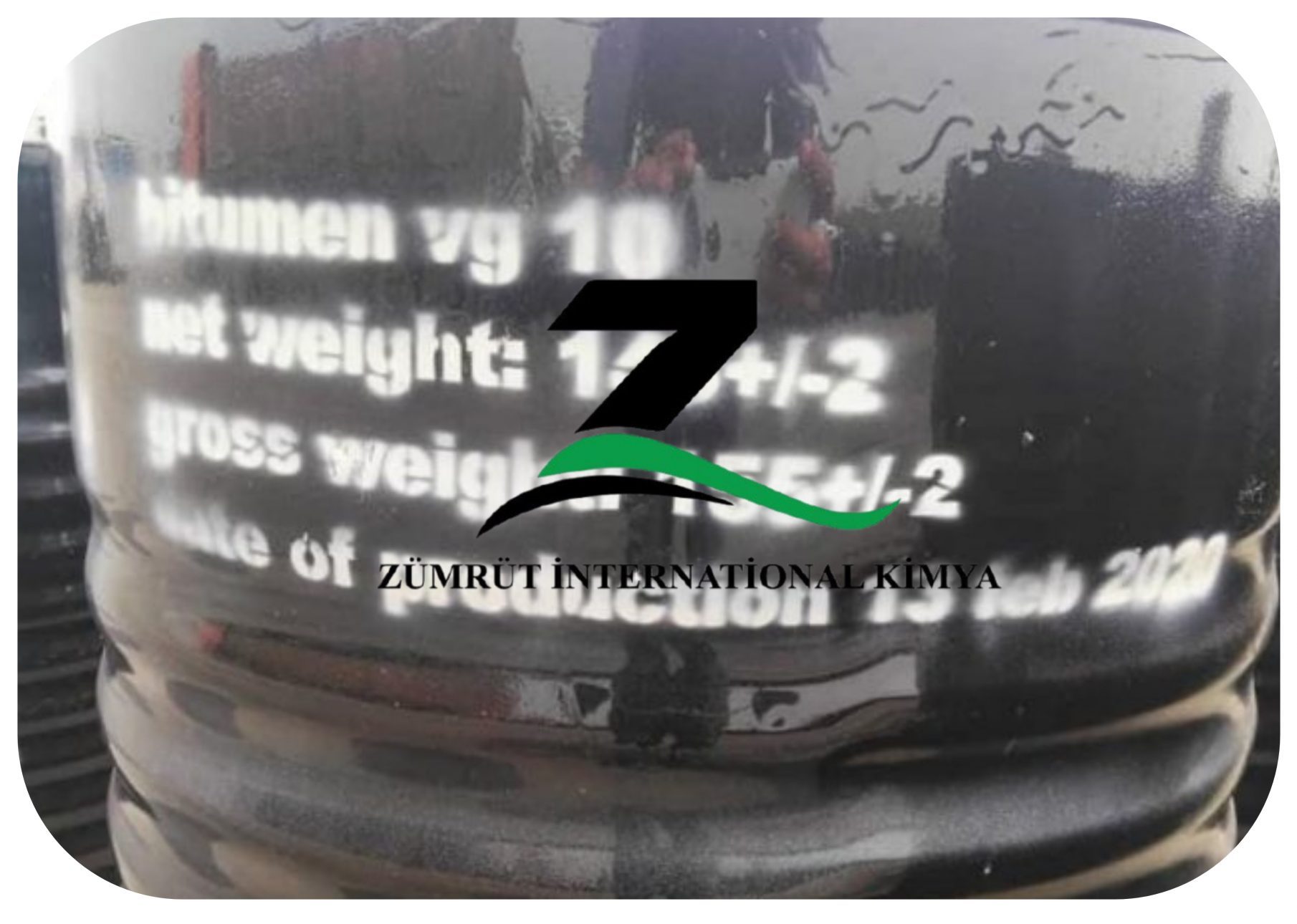

How Is Bitumen VG10 Packed?

Bitumen VG10 is packaged to meet diversified shipping and storage needs for construction projects:

Steel Drums: 180 kg drums, 110 drums per 20 ft container for small consignments.

Bitubags: 375 kg bags, 24 metric tons per 20 ft container.

Bulk Shipments: 2,000–20,000 metric tons in bitumen carriers for mass-scale projects.

Flexi Bags: 20 metric tons per bag for flexible bulk transportation.

Truck Tankers: 25 metric tons per tanker for local deliveries.

These packaging forms ensure safe and effective delivery for both mass-scale and small-scale projects.

Why Use Bitumen VG10 for Your Project?

Bitumen VG10 is a top choice for cold-weather road construction due to its unique features:

Low Viscosity: Ideal for spray application and surface dressing.

Flexibility: Spreads for crack resistance at low temperatures, yielding durable roads.

Versatility: Allows hot mix asphalt, emulsion bitumen, and tack coat compatibility.

Choose VG10 for durable, high-performance roads in harsh weather. Contact us to find out how VG10 can help your next paving job be a success.

Specification

| Specification | Unit | Value | Test Method |

|---|---|---|---|

| Absolute Viscosity, at 60 ◦C | Poise | Min 800 | ASTM D4402 |

| Kinematic Viscosity, at 135 ◦C | CST | Min 250 | ASTM D2170 |

| Flash Point | ◦C | Min 220 | ASTM D93 |

| Solubility in Trichloroethylene | %WT | Min 99 | ASTM D2042 |

| Penetration Value, at 25 ◦C | 0.1mm | 80-100 | ASTM D5 |

| Softening Point | ◦C | Min 40 | ASTM D36 |

| Viscosity Ratio, at 60 ◦C | ◦C | Max 4 | ASTM D4402 |

| Ductility at 25 ◦C , after thin film oven test | Cm | Min 75 | ASTM D113 |