General Description

SBS Modified Asphalt Crack and joint sealer is a high performance, single component, solvent-free SBS modified asphalt-cement compound used for reliable pavement and road repair applications in civil engineering works.

SBS Modified Asphalt is applicable over both asphalt and concrete to serve the purpose of long-lasting

restoration of ageing substrates. Due to its high viscosity SBS Modified Asphalt acts as an excellent sealer for obstinate cracks in asphalt accommodating for projected longitudinal and transverse contraction and expansion movements. SBS Modified Asphalt seals cracks up to 30 mm wide vvith a good 70% PCI at surrounding area.

Prior to application, crocks and joints shall be routed to create a uniform and consistent reservoire for the sealant. Nominal dimensions vary between 15mm wide x max 20mm deep. The crack should be thoroughly cleaned out internally and externally to remove any rubble or debris. In the event moisture is detected: the location must be thoroughly dried out by hot air lance prior to application. Work should not commence if rain or dust storms is imminent. In cold weather, pavement may be warmed up with a hot air lance. Sealing should not be done soon after rain when moisture remains In the cracks and joints.

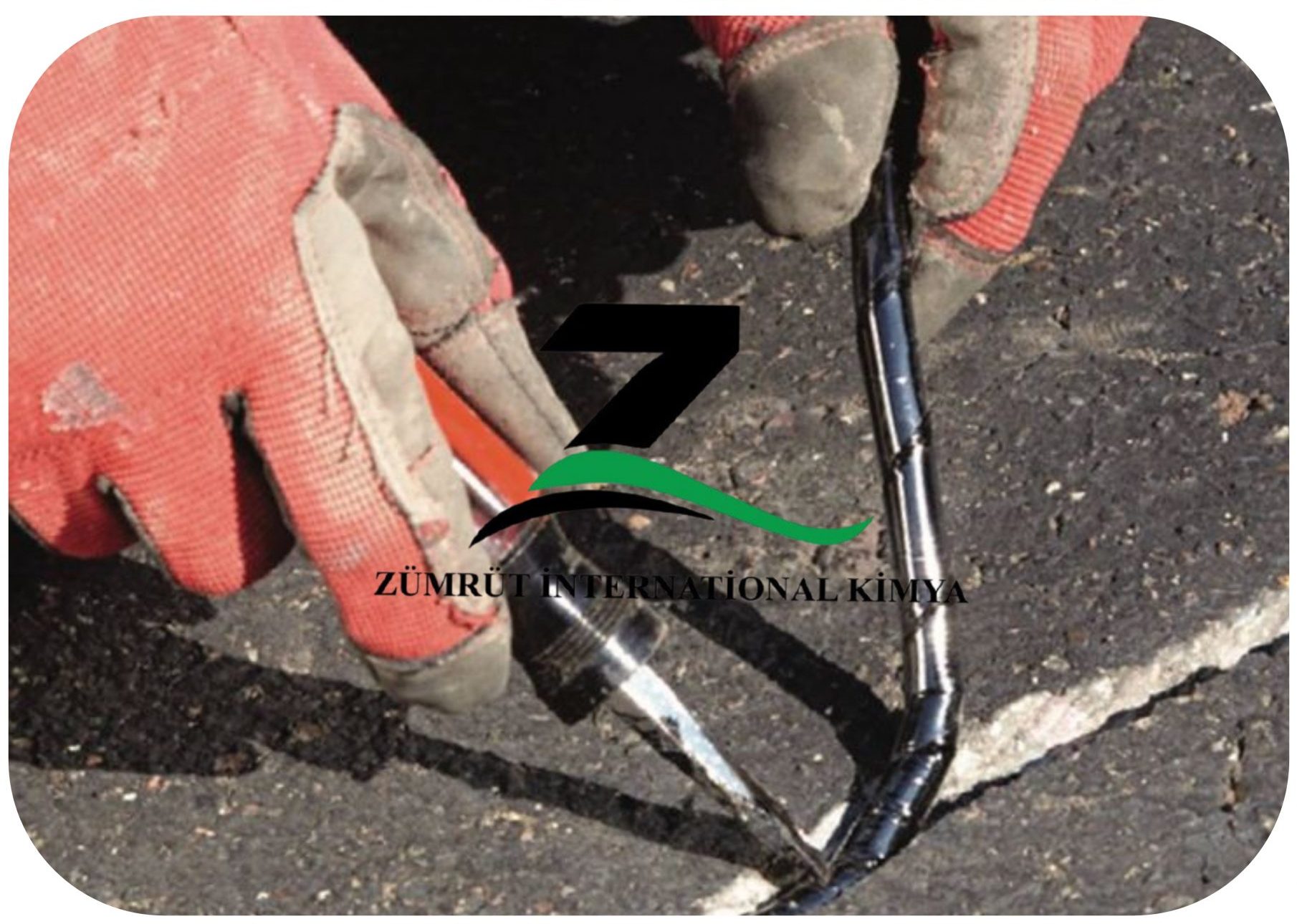

Application of SBS Modified Asphalt Crack Sealer

The pavement temperature should be above 5 °C at the time of sealing. Pour the melted material into the crack or joint directly by means of hand-held pol. cone. nozzle. or wand applicator. Remove any excess of material to maintain a leveled pavement surface. SBS Modified Asphalt shall be applied evenly from bottom to top while avoiding formation of entrapped air.

Protect from traffic flow until the sealant has cooled down and fully cured to avoid slicking to moving trafic. Where time is critical for traffic, Portland cement powder may be appied over the applied sealant for faster curing.

Usage of SBS Modified Asphalt Crack Sealer and Joint sealing

- Bridges

- Roads

- Highways

- Concrete slab expansion joints and cracks

- Airport runways, aprons and airfield

- Public asphalt paved areas

- Crack sealing after milling and before new asphalt overlay

Advantage of SBS Modified Asphalt Crack and Joint Sealing

- Single component

- Solvent-free

- Durable & long service life

- Corresponds to internationally recognized standards Excellent adhesion strength

- High elasticity (expansion and contraction properties)

- Stable at high and low pavement temperature conditions

- Excellent barrier against sand and moisture infiltration

Healthy and Safety of SBS Modified Asphalt Crack Sealer

All safety measures should be observed during installation Fire extinguishers should be kept nearby and handy on site. Installation personnel should wear protective gear at all times during installation.

Packing of SBS Modified Asphalt Crack Seale

SBS Modified Asphalt packing in 180 Kg New Still Drum an 25 Kg Karton box and also 20 Kg pail.

180 Kg New Still Drum

25 Kg Karton Bo

20 Kg Pail

Specification of SBS Modified Asphalt Crack Sealer and Joint sealer

ASTM D 5078: Standard Specitication for Crack Filler, Hot-Applied, for Asphalt Concrete and Portland Cement Concrete Pavements .

ASTM D 5167: Standard Practice for Melling of Hot-Applied Joint and Crack Sealant and Filler for Evaluation.

| Property | Typical Value | Test Method |

|---|---|---|

| Viscosity@ 204 °c (400 °F) | 100 poise Maximum | Brookfield |

| Softening Point | 99 °c Minimum | ASTIVI D 36 |

| Flow @60°C (140°F) | 3.0 mm, 5h, Maximum | ASTIVI D 5329 |

| Cone Penetration@25 C (77°F) | 45 dmm Maximum | ASTIVI D 5329 |

| Ductility@ 25°c (77°F) | 30 cm Manimum | ASTIVI D 113 |

| Asphalt compatibility | Pass | ASTIVI D 5329 |

| Resilience (Recovery)@ 25°C (77 °F) | 30 %Minimum | ASTIVI D 5329 |

| Recommended application temp. | 180 -204 °C (356 °F - 392 °F) | ASTIVI D 5167 |

| Maximum heating temp. | 204 oc (392 °F) | ASTIVI D 6690 |