Description

Slurry Seal systems (slurry seal and micro surfacing) are thin emulsion cold mixed overlays which are recognized as cost-effective restorative and preventive maintenance techniques for roadways of most traffic levels, airport runways and taxiways, highways, shoulders, sidewalks, foot and cycle paths, and parking lots. They may also be used as wearing courses on emulsion stabilized bases or recycled roadways, bond courses, crack fill or combined with other techniques like chip seal .

The asphalt surface of roads can deteriorate over time due to various factors, including weather conditions like frost, sunlight, and heat, as well as road salting, snow removal, and the impact of heavy traffic. Friction from tire chains and snowplow blades further accelerates wear, leading to issues such as erosion, raveling, aggregate loss, honeycombing, and sulphate attacks. Neglecting timely repairs and overlay installation allows these damages to worsen, potentially resulting in complete failure of the road surface and its underlying layers. To prevent such deterioration, the application of protective layers is highly recommended. These layers not only help maintain the road’s condition but also postpone the need for overlays, fill cracks, and provide waterproofing to protect both the asphalt and its sublayers.

Slurry seal is an effective and economical solution for road maintenance and preservation. It consists of a cold mixture of fine-graded aggregate, asphalt emulsion, mineral fillers, polymers, and water, applied as a surface treatment. While it serves as a preventive and corrective maintenance measure, slurry seal does not enhance the structural strength of the pavement. By incorporating polymers into our slurry seal formulations, we ensure greater durability and versatility, meeting the specific needs of each application through tailored mix designs.

This technique involves spreading a mixture of aggregate, water, and bitumen emulsion over the road surface to improve texture, waterproofing, and durability. Slurry seal also includes the addition of fillers, such as cement, and requires specialized paving equipment for application. Beyond filling voids, it enhances surface resistance, making it an essential method for prolonging the lifespan of asphalt pavements.

Slurry seals, typically have three aggregate gradations:

Type 1 (fine)

This type has the finest aggregate gradation (smaller than 2.36 mm) and is used for filling small cracks. They are used as a preparatory pavement treatment and are limited to low traffic areas.

Type 2 (general)

This type is coarser than the Type 1 slurry, and is the most commonly used slurry seal type. It treats surfaces with moderate raveling, and improves the skid resistance of the existing pavement.

Type 3 (coarse)

Type 3 slurry seals consist of the coarsest gradation and is used to treat surfaces with slight depressions, to prevent water ponding and reduce the probability of hydroplaning.

How thick is slurry seal?

The thickness of slurry seal depends on the type of material used, the condition of the pavement, and the desired outcome. Generally speaking, a slurry seal should be applied at a minimum thickness of 1/4 inch (6 mm). For more severe pavement defects or for areas with high traffic volumes, thicker layers may be necessary. The maximum recommended thickness is usually 1/2 inch (12 mm).

How much does slurry seal cost?

The cost of slurry seal depends on several factors, such as the type of material used, the condition of the pavement, and the desired outcome. Generally speaking, a slurry seal can range from $0.50 to $2.00 per square foot (5-10 $ per square meter – m2). The cost may also be affected by labor costs and other associated expenses. It is important to note that slurry seal is an economical.

How do we Apply a Slurry Seal?

Slurry seal application may be accomplished manually or by the utilization of a spreader box, depending on roadway length and complexity. The objective is to fully saturate the asphalt surface and evenly apply the slurry across the entire roadway. A proper assessment of the pavement condition must be made before application. This includes inspection of surface cracks, water damage, and other signs of deterioration to determine if slurry sealing is necessary or if other work needs to be performed.

Once the pavement is in condition, and required pre-treatments such as crack sealing have been performed, the slurry seal process occurs. The surface is first swept clean of dust and debris, and then one or more even layers of slurry are applied. Once the emulsion hardens and sets, additional coats can be put on as needed. Roads typically reopen to traffic in a few hours, with speed limits up to 30 km/h (18 mi/h) to provide sufficient setting and strength.

Key Factors to Consider for Slurry Seal Design

An efficient slurry seal is designed by paying proper attention to a number of key factors that will ensure the surface performs well during its service life. Among these, the major ones which determine the effectiveness of the slurry seal are traffic conditions, aggregate shape, characteristics of the existing surface, and material compatibility. Dealing properly with these aspects will greatly increase the prospects of having a sound and long-lasting slurry seal.

Traffic Conditions

Type and volume of traffic are very important in the type of asphalt emulsion applied, as well as the required aggregate gradation. Clearly, the formulations for high volumes of traffic must be more robust to resist wear.

Aggregate Shape

Shape of the Aggregates Aggregates used in the mix are to be measured in both their aggregate quantity and volume of asphalt emulsion needed. Angular aggregates provide better interlock and thus overall performance of the slurry seal.

Characteristics of the Existing Surface

The current surface condition and texture determine the type of aggregate that may be used, quantity, and rate of application for the emulsion. A well-assessed surface will guarantee that the slurry seal adheres properly and with the best results possible.

Material Compatibility

Considering all of these factors at the design process, materials will be able to be mixed in appropriate proportions to make a semi-fluid, homogeneous mix of slurry. This helps in the performance of the seal and its specific intended applications as well.

Designing for the criteria listed will ensure a proper slurry seal that provides satisfactory service life, and pavement maintenance will be sufficiently served.

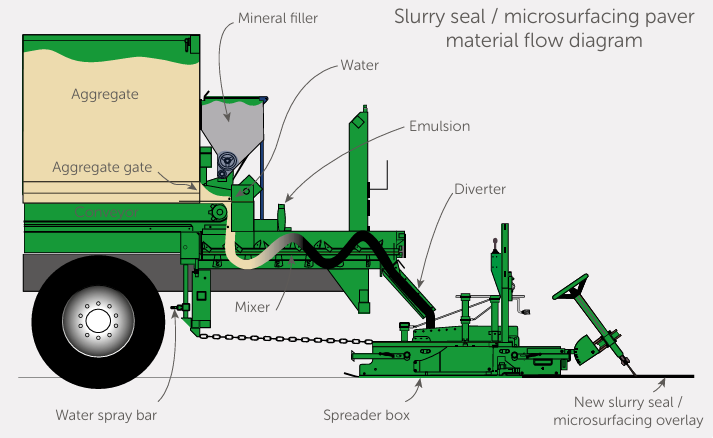

Application

Slurry surfacing is normally applied on highways using a purpose-designed self-propelled mix-paver but may be prepared in more basic mixing equipment and applied manually for smaller scale applications. The slurry ingredients are dosed and mixed in the paver then discharged into a spreader box which distributes the material over the roadway and maintains the profile and thickness of the seal. Application rates range from 3-14 kg/m2 for a single pass. Some specially formulated materials may be applied in multiple layers or in deeper deformations or potholes. Bond coat is sometimes applied before sealing to ensure that the new layer adheres to the existing surface.

Slurry seal is a versatile and cost-effective method for preserving and restoring road surfaces. The process involves several carefully planned steps to ensure durability, improved surface texture, and waterproofing.

First, surface preparation is critical. The road must be thoroughly cleaned to remove dust, debris, and loose particles using a power sweeper or air blower. Any potholes, cracks, or surface irregularities should be repaired and allowed to cure before the slurry seal is applied.

Next, the mix preparation phase involves blending fine-graded aggregate, bitumen emulsion, water, mineral fillers (such as cement), and occasionally polymers. This mixture is combined to form a semi-fluid, homogeneous slurry with uniform material distribution.

The application process follows, using a specialized slurry seal paving machine to evenly distribute the mixture across the surface. The slurry is applied in a thin layer, typically 3-6 mm thick, depending on the road’s condition and traffic demands. In some cases, a pneumatic-tired roller is used to compact the surface, ensuring better bonding and uniformity.

Curing is essential after application. The slurry seal must be allowed to dry under appropriate weather conditions, which usually takes several hours. During this period, traffic should be restricted to avoid premature damage.

Traffic control plays a key role during application and curing, ensuring that the seal remains undisturbed and traffic flow is managed effectively.

Finally, a post-application inspection ensures the surface meets quality standards. The surface is checked for uniformity and proper bonding, and any loose particles are removed to maintain its integrity and quality.

By following these steps, slurry seal provides a durable, cost-effective solution for extending the life of road surfaces while enhancing safety and performance.

Quality Control

Quality assurance and quality control The paver has to be calibrated before use. The aggregate may be damp which affects its bulk density and the delivery using volumetric gate type feeders. In many cases a test strip will be laid. During construction the consumption of materials is carefully monitored as a double check on the metering systems. Modern pavers have integrated data-loggers which provide a record of material consumption. The quality of ingredients may be tested during construction. The slurry may be sampled for bitumen determination and performance tests may be performed with site materials or using the slurry discharged from the paver. The fresh seal should have an even color and texture with little or no run off of emulsion from the sides. Workers may correct small imperfections and drag marks in the seal before it cures using squeegees or brooms.

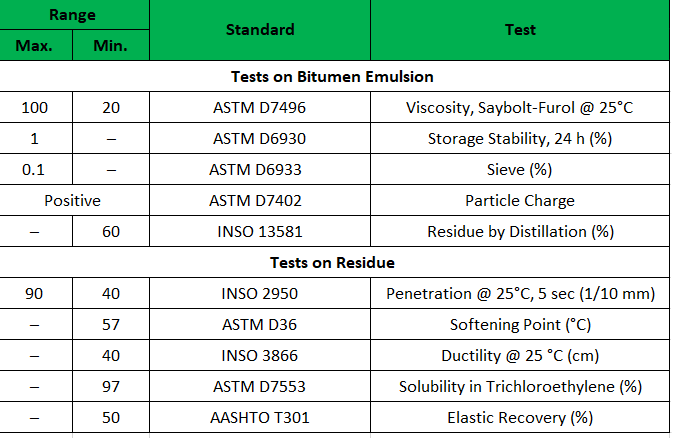

Standard requirements for tests of bitumen emulsion for slurry seal