Intro

Understanding the key differences in slurry seal vs. micro surfacing can help you choose the best pavement treatment for durability and performance. As asphalt ages and deteriorates, the treatment changes, resulting in higher treatment and repair costs. Luckily, micro surfacing and slurry sealing are pavement resurfacing techniques that can extend the life of your asphalt without breaking your budget. In this article, we’ll discuss some of the differences between micro surfacing and slurry sealing and examine the various advantages that each resurfacing option provides.

What is Slurry Seal?

Slurry seal is a cold-mix paving treatment first introduced in Germany during the 1930s, designed to preserve and extend the life of existing asphalt surfaces. Unlike traditional seal coats, it combines fine crushed aggregate, water, emulsified asphalt, and specialized additives into a uniform mixture applied directly to the pavement.

The asphalt emulsion serves as a binder, locking the aggregate in place and forming a strong bond with the surface. While it doesn’t add structural strength, slurry seal is an economical solution for preventive maintenance, offering enhanced surface protection without the need for heat during application.

Slurry Seal Process

Slurry seal is a mixture of mineral aggregate, cationic asphalt emulsion, water, and additive on a suitably prepared surface. The emulsion used for slurry seals may be neat or polymer modified, with additional additives such as Portland cement, hydrated lime or break control agents.

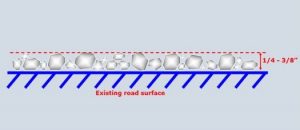

ISSA classifies aggregate by three gradation types: Type I, II, III with Type I being the finest and Type III the coarsest. A high fine content is required to form an asphalt mastic which acts as a binder to ensure waterproofing and adhesion. Larger chips provide abrasion resistance and surface texture but do not add structural strength.

Slurry seal best serves the low volume roads, secondary roads, and residential streets. Applications should not exceed 1.5 times the thickness of maximum aggregate size. Addition of polymers increases durability and cohesion without affecting structural capacity to carry heavier loads.

Micro-surfacing Description

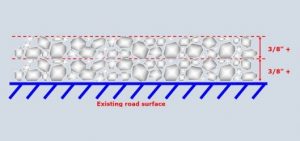

Slurry Seal was expanded upon in the late 1960’s and early 1970’s in an attempt to use slurry in thicker applications that could be applied in narrow courses in wheel ruts to avoid not having to replace expensive traffic delineation on the autobahns. High quality aggregates and advanced emulsions where incorporated which resulted in a stable product when applied in multi-stone thickness. Micro surfacing can be applied in multi-layer surfaces.

Micro Surfacing Process

Micro-surfacing, like slurry seals, is also a mixture of mineral aggregates, cationic asphalt emulsion, water, and additives. The difference mainly lies in the quality of the aggregate and asphalt emulsion used. The quality of aggregates in micro surfacing is high, similar to the stone used in Super pav hot mix, whereas the emulsion is always polymer modified with a higher dosage of polymer usually in the range of 3-5%.

The high-quality aggregate forms a mineral skeleton that forms the main structural element. The asphalt mastic binds the stone matrix as in an SMA mix. Such a result, strong enough is able to provide adequate strength for heavy traffic conditions, making it a suitable surface treatment for the arterial roads and freeways. A well-designed micro surfacing will also fill ruts in hot mix asphalt and support very heavy traffic loads without loss of performance.

How Do Micro-Surfacing and Slurry Sealing Differ?

Micro-surfacing and slurry sealing are both beneficial methods of maintaining asphalt surfaces, but they serve distinct purposes. Micro-surfacing is a preventative treatment that seeks to delay the replacement of an entire road, while slurry sealing is a reactive treatment, used to repair damage that has already been done.

One of the major differences is that the two systems cure differently. Slurry seal relies on sunshine and low humidity to evaporate the water within the emulsion, whereas micro-surfacing asphalt emulsion contains chemical components that force out the water to cure irrespective of specific weather patterns or evaporation.

Micro-surfacing is also a faster process than slurry sealing, so it is a better option if weather conditions will prevent the application of slurry sealing effectively. Micro-surfacing also has better resistance to power steering marks due to the polymers in it and is able to shed small aggregates more effectively.

Conclusion

Choosing between Slurry Seal vs. Micro Surfacing depends on the specific needs of your pavement. Slurry seal is a cost-effective solution for maintaining low-volume roads and addressing surface wear, while micro surfacing is a more advanced treatment designed to handle heavy traffic loads and prevent long-term deterioration. The key difference lies in their application process, material composition, and performance—with micro surfacing offering faster curing, greater durability, and structural strength. By understanding these distinctions, you can select the best resurfacing method to extend the lifespan of your asphalt while optimizing maintenance costs.

Slurry Seal vs. Micro-Surfacing Comparison Table

| Aspect | Slurry Seal | Micro-Surfacing |

|---|---|---|

| Origin | Developed in Germany in the 1930s | Evolved in the late 1960s–70s to address thicker applications on high-traffic roads |

| Purpose | Reactive maintenance for aged pavements | Preventative maintenance to delay road replacement |

| Main Components | Fine aggregate, cationic asphalt emulsion, water, additives (e.g., Portland cement, lime) | High-quality aggregate (like Superpave), polymer-modified emulsion (3–5% polymer), water, additives |

| Aggregate Quality | Moderate to low | High (multi-layer mineral skeleton, durable under traffic loads) |

| Emulsion Type | Cationic asphalt emulsion; may or may not be polymer modified | Always polymer-modified with higher polymer dosage |

| Application Areas | Low-volume roads, secondary roads, residential streets | Arterial roads, highways, and high-traffic zones |

| Layer Thickness | Typically ≤1.5x the maximum aggregate size | Can be applied in multi-stone thickness (e.g., for rut filling) |

| Structural Strength Contribution | No | Yes – contributes to strength, fills ruts, supports heavy traffic |

| Curing Method | Ambient cure—relies on sun and low humidity | Chemical cure—reacts independent of weather (faster set time) |

| Cure Time | Slower | Faster |

| Durability | Moderate | High—better resistance to steering marks and aggregate shedding |

| Performance Under Load | Not suitable for heavy traffic | Designed to handle heavy traffic and resist deformation |

| Cost | More cost-effective; economical for minor maintenance | Higher initial cost but better long-term performance |

| Application Use | Seals minor cracks, restores surface, limited to aesthetic/functional fixes | Seals and levels surface, fills ruts, increases skid resistance, improves surface structure |

| Ideal Weather Conditions | Warm, dry, sunny | Can be applied in varying weather due to chemical setting |

| Summary Use Case | Budget-friendly treatment for aged, low-volume roads | Advanced treatment for busy roads that require structural and functional preservation |