Caustic Soda Flakes Description

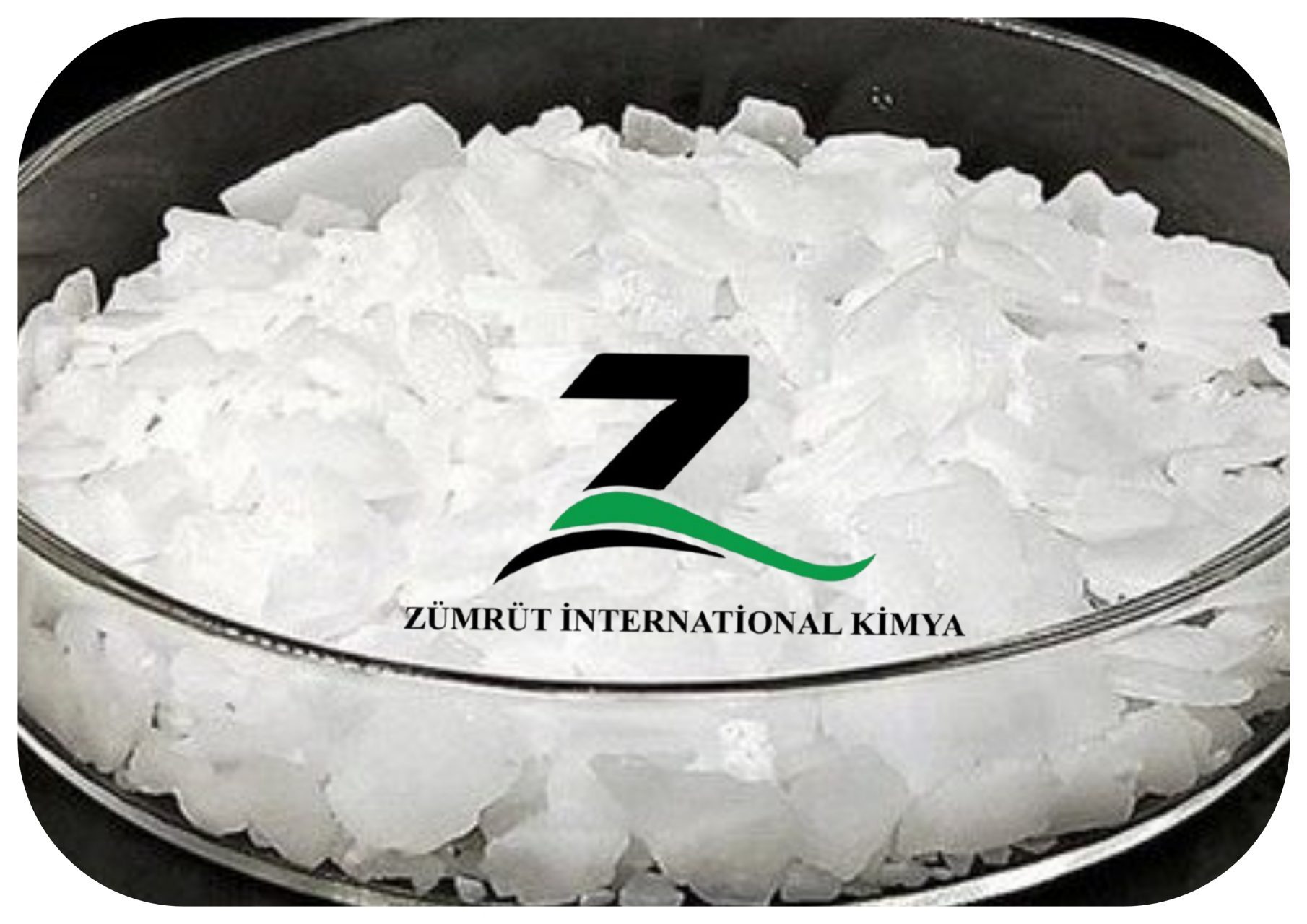

Caustic Soda Flakes, also known as sodium hydroxide, is a highly caustic and alkaline chemical compound used in industrial and commercial applications. It is a white, solid substance with a crystalline appearance and is soluble in water and alcohol. It is classified in the group of corrosive chemicals and is obtained by evaporating liquid caustic soda.

Caustic Soda Flakes used in various industries, including synthesis of organic compounds, refining petroleum products, textile production, paper making, soap making, aluminum metal production, sodium preparation, and glass making.

The chemical is classified as solid sodium hydroxide or caustic soda, and is obtained by evaporating liquid caustic soda. The chemical is classified as sodium hydroxide (Natrium hydroxide) and is also known as sodium hydrate.

If you come across the following common names in the caustic soda flake market, it means the same alkaline substance:

solid sodium hydroxide; sodium hydroxide; caustic soda; Caustic soda NaOH, solid NaOH; caustic soda NaOH; Sodium hydroxide (Natrium hydroxide); sodium hydrate; caustic soda; caustic soda 98%

Caustic Soda Flakes Application

The Caustic soda flakes is widely used in a number of industrial processes:

Caustic soda flake constitutes an essential reactant in the production of many useful organic chemicals (more than 32 % of caustic production goes into this application).

Caustic Soda Flakes is uses in, Inorganic chemicals like paints, glass and ceramics and uses in fuel cell production and cosmetics are also very important.

The paper, pulp and cellulose industries are major users of caustic soda flakes.

Other areas where caustic soda flake is essential are: the food industry, water treatment (for the flocculation of heavy metals and acidity control), the soaps and detergents sectors, the textile sector (as a bleaching agent), mineral oils (preparation of greases and fuel additives) and the synthesis of the synthetic fiber rayon.

About four percent of caustic soda flake production is used in the process of refining aluminum from its ore bauxite.

The remainder of the caustic soda flake production has miscellaneous applications, like the synthesis of pharmaceutical compounds, rubber recycling and the neutralization of acids.

production process

Caustic soda is produced through two methods: causticization and electrolysis. The causticization method involves converting soda ash and lime into soda alkali solutions, which are then clarified and concentrated to over 40%. This liquid is then solidified to create a solid caustic soda product. The causticizing mud is washed with water for alkalizing.

The trona causticization method involves pulverizing and dissolved Trona, then adding it to lime milk at 95-100 ℃ for causticization. The solution is then clarified and concentrated by evaporation to a NaOH concentration of about 46%. The clear liquid is cooled and further concentrated after salt analysis to prepare a solid caustic soda product.

Diaphragm electrolysis involves adding soda ash, caustic soda, barium chloride fine preparation, sodium polyacrylate or causticized Bran, and hydrochloric acid for neutralization. The brine is preheated and sent to electrolysis, preparing liquid caustic soda and further concentrated to obtain a solid caustic soda product. The salt mud is washed with water for salt reduction.

The ion exchange membrane method involves refining the original salt water, filtering it through a microporous sintered carbon tubular filter, and then undergoing secondary purification using a chelating ion exchange resin tower. The secondary refined brine is electrolyzed to generate chlorine in the anode chamber, sodium hydroxide in the cathode chamber, and hydrogen gas in the cathode chamber. High purity hydrochloric acid is added to neutralize the returned OH-, and pure water is added to the cathode chamber.

Handling and Storage

When handling caustic soda flakes, it is crucial to follow proper safety precautions. Wear protective gloves, goggles, and clothing to prevent direct contact with the flakes. Work in a well-ventilated area to avoid inhaling fumes. Store caustic soda flakes in a cool, dry, and well-ventilated space, away from moisture and incompatible materials. Keep the flakes tightly sealed in their original container and ensure proper labeling for easy identification. Be cautious as caustic soda flakes are highly corrosive and can cause severe burns, so handle them with care and follow appropriate safety guidelines.

Packing

There are different kind of packing for industrial caustic soda flakes, since caustic soda /sodium hydroxide is chemical product better to pack in 25 kg 2 layer laminate PP bag and don’t allow any water to moisture enter the bag , also for transportation and reducing labor charges we can put bags in 1250 Kg jumbo bag or 1250 Kg pallets are possible.

Analysis

| CONTENT | TEST RESULT | UNIT |

|---|---|---|

| Al2O3 | Max 3 | PPM |

| Fe | 10 | PPM |

| Heavy Metals as Pb | Max 2 | PPM |

| Insoluble in Water | 0 | %W |

| Na2CO3 | 0.43 | %W |

| Na2SO4 | 0.0047 | %W |

| NaCl | 0.0085 | %W |

| NaOH | 98%±1 | %W |

| SiO2 | 0.0019 | %W |

| SHAPE | 0.3-1 | CM³ |